COOLANT Ozone Recycling Oil Water Separator

- CERAMIC PLATE method, eliminating TUOUBLE of ozone generator.

- Unlike other KR companies, Our company is the first in Korea to use both the refrigeration type and the adsorption type so that Air pre-treatment was configured, and an after-cooler was installed in addition to the after-cooler installed in the compressor to lower the dew point of the air as much as possible so that ozone generation was uniform.

Principle

In the past, there are lots of companies in Korea that used only one of refrigeration or adsorption dry for pretreatment of air. But we Donghae Industry are applying additional separate after-cooler to lower the dew point of the air as much as possible so that ozone generation was uniform.

In addition, we had developed a medium-frequency inverter and transformer, we export applied a stable ozone generator module of the ceramic plate method to complete the development and a high-concentration ozone generator. Thru this new method we had solved the trouble of ozone generator frequently occurring in other companies.

In the past, there are lots of companies in Korea that used only one of refrigeration or adsorption dry for pretreatment of air. But we Donghae Industry are applying additional separate after-cooler to lower the dew point of the air as much as possible so that ozone generation was uniform.

In addition, we had developed a medium-frequency inverter and transformer, we export applied a stable ozone generator module of the ceramic plate method to complete the development and a high-concentration ozone generator. Thru this new method we had solved the trouble of ozone generator frequently occurring in other companies.

-

OZONE MODULE

OZONE MODULE -

O2 MAIN CONTROLLER(PCB)

O2 MAIN CONTROLLER(PCB) -

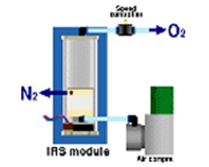

OZONE PRINCIPLE

OZONE PRINCIPLE -

O2 PRINCIPLE

O2 PRINCIPLE

1. Composition : AIR FLOW METER + AIR COOLING + OZONE Generator + INVERTOR HIGH TRANS + INJECTOR LINE

2. Performance : It easily decomposes unsaturated organic substances and aromatic compounds into low molecular substances by ozone treatment and sterilizes water bacteria perfectly.

3. Application Fields : color treatment of dyeing wastewater, food and beverage process sterilization, swimming pool water sterilization, gray water, various wastewater treatment

4. Usage :Aquaculture farms, sewage treatment plants, general public restaurants, water purification plants, swimming pools, wastewater treatment plants, anti-corruption in COOLANT

2. Performance : It easily decomposes unsaturated organic substances and aromatic compounds into low molecular substances by ozone treatment and sterilizes water bacteria perfectly.

3. Application Fields : color treatment of dyeing wastewater, food and beverage process sterilization, swimming pool water sterilization, gray water, various wastewater treatment

4. Usage :Aquaculture farms, sewage treatment plants, general public restaurants, water purification plants, swimming pools, wastewater treatment plants, anti-corruption in COOLANT

Specification

※ You can check the contents by scrolling left/right.

| MODAL | SIZE (W*D*H) |

GENERATION | TYPE | POWER CONSUMPTION | SUPPLY DEMEND GAS | ||

|---|---|---|---|---|---|---|---|

| Air | Oxygen | ||||||

| CUSTOMODER | DH OZONE-10 | 500*350*750 | 10g/hr | CAVINET | 250W | 15LPM | - |

| DH OZONE-20 | 550*360*850 | 20g/hr | CAVINET | 850W | - | 5LPM | |

| DH OZONE-30 | 650*450*1200 | 30g/hr | CAVINET | 1500W | - | 10LPM | |

| DH OZONE-40 | 700*500*1250 | 40g/hr | CAVINET | 1800W | - | 20LPM | |

| DH OZONE-50 | 750*550*1300 | 50g/hr | CAVINET | 1KW | 50LPM | - | |

| DH OZONE-100 | 850*650*1500 | 100g/hr | CAVINET | 2KW | 100LPM | - | |

| DH OZONE-200 | 900*700*1600 | 200g/hr | CAVINET | 3KW | 200LPM | - | |

| DH OZONE-300 | 1000*750*1700 | 300g/hr | CAVINET | 4KW | 300LPM | - | |

| DH OZONE-400 | 1300*800*1800 | 400g/hr | CAVINET | 5KW | 400LPM | - | |